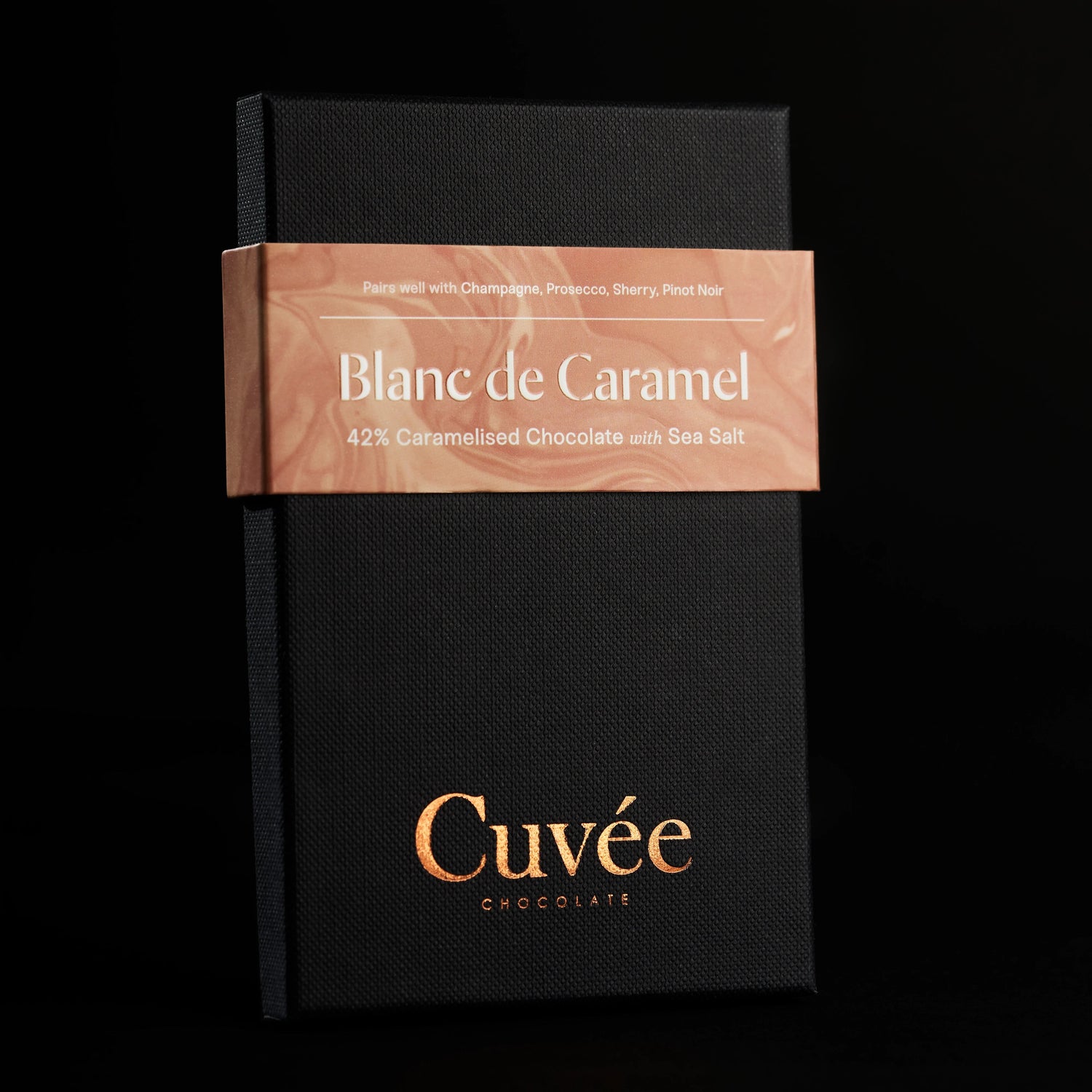

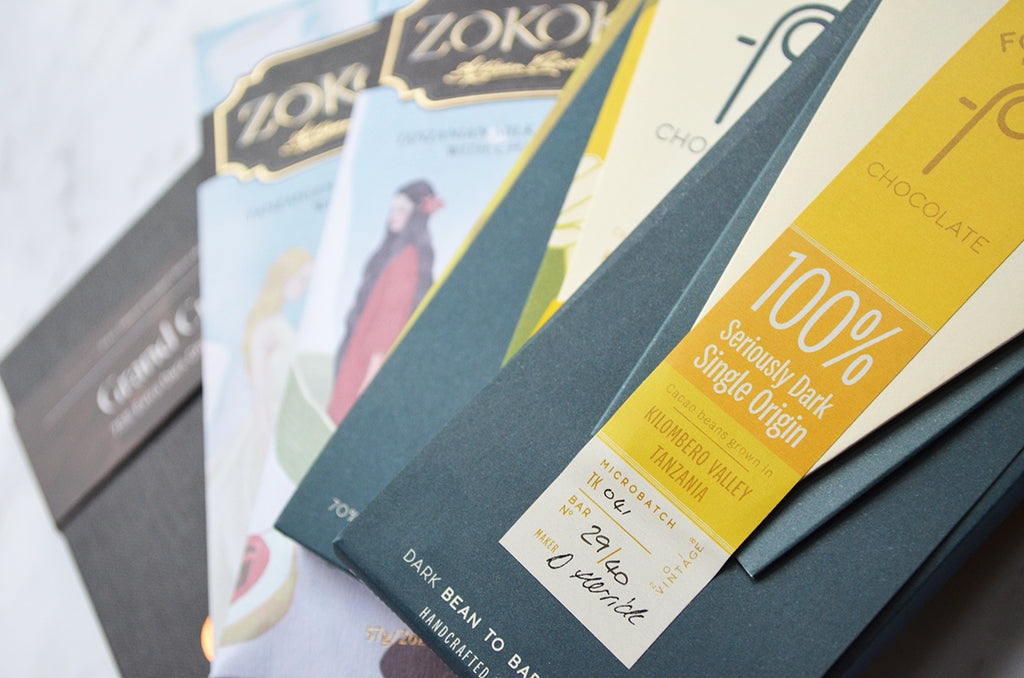

For my latest interview I caught up with Simran Bindra, co-founder of Kokoa Kamili in Tanzania. Simran and his team work with around 2000 small-scale farmers in the Kilombero Valley area. They buy high quality beans at well-above market rates, expertly ferment them at their facility in Mbingu, and then distribute them to some of the world's best chocolate makers. Many of our customers will be familiar with Kokoa Kamili as we have featured many great bars made with these beans, including the Foundry Chocolate Tanzania 70%, which was one of the first New Zealand-made bars to ever win an Academy of Chocolate award. The Cuvée Chocolate Grand Cru 75% is also made with these beans, and will feature in our July 2020 subscription boxes.

What is your background and what led to the creation of Kokoa Kamili?

My co-founder Brian and myself spent most of our careers working in international development and I believe we both left for similar reasons - wanting to look at using business to set up a more long term, sustainable solution for increasing farmer incomes. There are three main things that impact the quality of cocoa beans - the genetics of the trees, the terroir, and then the post-harvest handling - we knew that in Tanzania we had interesting genetics, a good growing climate - but that we were dropping the ball on the fermentation and drying and as a result were not on the map as a fine flavour origin. We wanted to see if we could improve the reputation of Tanzanian cocoa, and increase farmer incomes while doing so.

What is your role in the company and what does your daily routine look like?

We are a small company so we both wear a lot of different hats - I handle more of the sales and marketing whereas Brian takes on the HR and finances - most of the rest of the tasks we have some overlap on. We have a small head office in Dar es Salaam where our families are, and split our time between Dar and our operations in Mbingu - a 10-12 hour drive away.

How does Kokoa Kamili decide which farmers to work with? Do you go looking for farmers, or do farmers approach you?

When we started out, we did a lot of outreach to farmers, a lot of meetings under mango trees introducing ourselves, explaining our proposed business model, etc. Once we had our first cohort of farmers on board, it spread pretty organically - we pay more than anyone else does so farmers started coming to us.

What are some of the impacts that Kokoa Kamili has had on farmers’ lives and the Tanzanian cacao industry?

We pay more money to farmers for their cocoa - that's more money in a farmer's pocket. What she spends that money on depends on her needs/priorities of her family - it might be expanding her farm, improving her home, sending her kids to a better school, or just some meat in the pot on Sundays! We also offer extension services - providing training on good agronomy practices, and seedlings from our nursery every year. For the broader Tanzanian cocoa industry - we're a very small player - we export maybe 1-2% of the country's crop, however, I think that we've been able to put Tanzania on the map as a source of high quality cocoa. We're proud to work with some of the world's best chocolate makers - every time we see a bar with Tanzania listed as the cocoa origin it's a little point of pride for us, our team, and the farmers that we work with.

What are some of the benefits of a centralised fermentation system?

Quality and consistency. If you want to have a consistent, high quality cocoa bean you have to be centrally fermenting beans. Small holder farmers typically only harvest every two weeks, and outside of peak season, will be getting too small a harvest to achieve a good fermentation. We have strict protocols and monitor each fermentation closely to ensure it meets our quality standards. When so much of the flavour development happens at this stage, it must be closely controlled to make sure you're getting the quality that the bean-to-bar market needs.

How do you ensure that farms are operating to the level of quality you require?

Each delivery of cocoa that we receive, whether it's 1kg or 500kg, is subjected to a visual inspection - if it doesn't meet our standards we don't accept it. Simple. We've done a lot of work to communicate our standards to our farmer network and so these days it's pretty rare for us to turn away beans, as farmers understand our requirements and abide by them. With regards to farming practices, we require all of the farmers we work with to sign a supplier code of conduct ensuring ethical and labour conditions on farms meet our standards.

How much cacao does Tanzania export? And roughly what percentage would be considered fine flavour?

Data is hard to come by, but we estimate that Tanzania's annual harvest is somewhere around 10,000MT. It depends on how you define fine flavour! We produce in the range of 100-140MT a year.

What are some of the biggest challenges in your work?

Unfortunately infrastructure is still very poor in our part of the country - the road to our facility is often inaccessible in the rainy season so it's a rush to get the cocoa out before the rains hit in full force. That being said, things have improved in the past seven years - we used to have to drive to the nearest cell phone tower to make a phone call and now we have decent WiFi at our facility! The current pandemic has hurt a lot of our customers very hard, and that has knock-on effects to bean demand. We are confident the bean-to-bar sector will manage to survive the pandemic, but I think it will probably have set our growth projections back a few years.

What are Kokoa Kamili’s hopes for the next five, ten or twenty years?

For the bean-to-bar industry to grow! We've got some great examples in coffee and craft beer on where chocolate can go. It's fascinating to see the different avenues that so many makers are going down, and we continue to look forward to innovation and development in the sector! In the next few years, we're planning on putting up a new facility a few kilometres down the road from our current location that will allow us to increase our volumes, and to play around with a few other experiments!

What are some of your favourite chocolate bars?

Anything made from Tanzanian beans of course!

Thanks so much to Simran for taking the time for this interview. If you haven't tried any bars made with beans from Kokoa Kamili yet, be sure to check out our Tanzania Collection. Enjoy!